Analysis

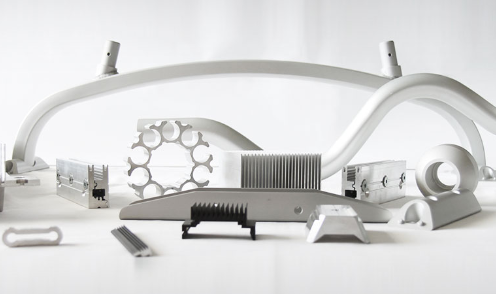

We provide the right solutions for each application. In order to produce effective high-quality end products, the first thing to do is to identify the end users and purposes of use

Design

We serve our customers as a product and process development partner. Careful design ensures that our products are manufactured in a way that ensures high quality and optimal performance.

Implementation

The durability, usability and reliability of our products is based on extensive expertise as well as certified quality and environmental management systems. A large portion of the aluminium used by Purso comes from recycled metal.

Life-cycle services

With us, the partnership does not simply begin with an order and end with a delivery, because we consider the entire life cycle of the solutions we provide. Because we have not outsourced our production, we can guarantee the continued availability of our products and services.